HEC was established in 2001. “We started by concentrating on structural steel structure itself as a discipline, says Sameer Dabbas. “Soon, though, we started to take on some civil contracting work. That made us realize that we needed to be able to add electromechanical disciplines, so we acquired a specialist company to give us that capability.”

From this point, it was a short step to start offering clients a design and build package. HEC’s attitude has always been more to meet the clients’ needs however these change, than to set limits on its capability. This way it has made a name for itself as the company to go to for fast track projects, where industrial clients from any sector can get their facilities up and running in time to meet their market demands. Now HEC has come to specialize in creating turnkey solutions in record time.

The structural steel manufacturing and fabrication plant in Abu Dhabi, established in 2008, has been growing continuously. “We are a long way from being able to supply all the steel we need for our own projects: currently we meet about 50 percent of the demand and outsource the remainder to reliable partners like Zamil Steel,” says Dabbas. “These are long term partners: we have built trust with them and we can rely on them to deliver so that in turn we can deliver for our clients. The name of our game is having a good team in house and then working with good supply chain partners. If you have these two things in the equation success is almost guaranteed!”

This is also true of international suppliers. Nearly 70 percent of HEC’s contracts are repeat orders from satisfied clients. “We have state of the art software, and have even developed our own ERP platform in-house, however we think the excellent personal relationships we retain with both clients and suppliers is just as important. As just one example he cites the French supplier of overhead travelling cranes he has been dealing with for 15 years. “They understand that we are serious, pay promptly, and that our end client’s interest is our own greatest interest.”

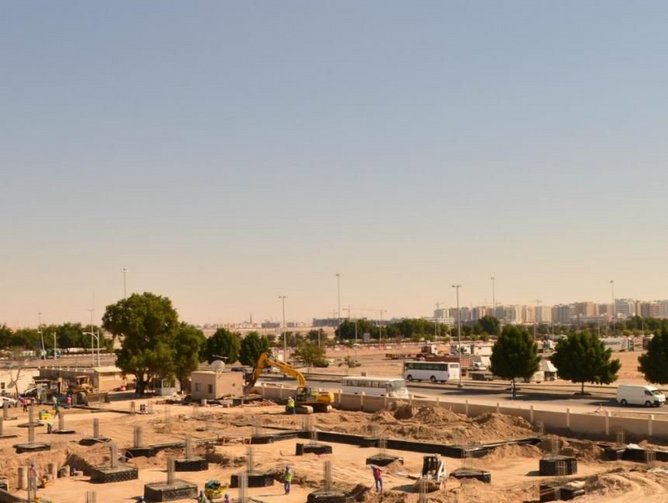

As investment in industrial diversification and the development of the UAE’s industrial cities intensifies, many local and international companies are occupying space within well-appointed zones like the Khalifa Industrial Zone (Kizad) in Abu Dhabi or the 14 square kilometer ICAD 1 located near to Musafah Sea Port and close to Abu Dhabi International Airport.

Having made the decision to invest, these companies need to get their facilities into production without delay, so they are turning to HEC in increasing numbers. For example, last year HEC completed a new manufacturing facility for UAE-based West Coast Company, a waste management specialist. The Kizad plant produces paper products from recycled materials, appropriately for what Dabbas calls one of a few industrial zones in the world that build according to strict environmental regulations.

An even more recent success story is just being finished, also at Kizad. This is the $13 million Polysys Additive Technologies Middle East (PATME) manufacturing plant. The factory produces polymer stabilizers and will have the initial capacity of 7,000 tons a year to serve the regional customers’ growing needs for these products. “The plant was completed in record time, says Dabbas. “The client gave us a target of ten months - and to get all the equipment installed, commissioned and powered up in that time was really a big challenge.” But the HEC project team managed to achieve this.

Time is money, he reiterates, and not just for industrial clients. Schools and universities also feature in the project portfolio, and often their expansion programs need to be completed within the vacation. HEC is proud of its reputation as a company that can unfailingly meet these tight schedules by innovative and flexible approaches to management and construction methodology. “Sometimes we elect to do things in parallel rather than in sequence; we may use factory-made modules as opposed to constructing on site, or pre-assembling electromechanical elements at the same time as doing the preparatory engineering. Techniques like this can cut the project time by as much a half!”

So he is relishing a project that sets an even tighter timeframe as HEC accepts challenge to build Morgan Advanced Materials’ first dedicated Middle East facility, again at Kizad. The London-based company is a global producer of fibre products, and this facility will initially focus on the production of high-temperature fibre products for use in sectors including oil and gas, aluminium, steel, energy, petrochemicals and fire protection. It’s HEC’s first contract with this client, but Morgan carefully monitored the Polysys construction to satisfy itself that HEC could deliver – with only eight months to complete a job that is not less demanding than PATME, it was clearly impressed. “They have to be in production by a certain date – that is understood by us all - so we work to their dates and draw up a plan with which they can be comfortable. They know exactly what they want and have been repeating the process all over the world,” says Sameer Dabbas.

So many projects are listed on HEC’s website, and so many more are in hand or projected that we couldn’t hope to give more than a taste of the company’s reach. However it’s worth mentioning a couple more. One is a new project for a client that has been coming to HEC since 2003. Al Masaood Marine is building a ship maintenance depot on the coast at ICAD, complete with heavy lifting, fabrication and workshop facilities. “We understand this business, and we understand how to execute it within the UAE regulations that are very rigorously applied in the industrial zones.”

HEC’s plans for regional expansion, particularly into rapidly growing areas within Saudi Arabia and Qatar for example, were to some extent put on hold after 2008 as the depression struck. Now, however, in an improving economic environment HEC has just increased its workforce by 10 percent to around 1,200 and is ready to expand beyond the UAE. It has started to bid for contracts in Saudi Arabia, says Dabbas, and it hopes that a recent contract award from a large Saudi Arabian company, establishing a new headquarters and logistics presence at the Dubai World Central, the new city that will be host to World Expo 2020, will help. Understandably Sameer Dabbas is upbeat about this development. “We are very happy they have put their confidence in us.”

At the end, HEC’s SOP is that it is able to deliver a turnkey project on time, beyond all regulatory requirements, ethically and with environmental sensitivity. Its success to date speaks for itself, but for the time being it is content to be the leading mid-size contractor in the region. That way it can keep the personal goodwill that lies at the core of its success.