How FLSmidth’s supply chain setup enhances customer productivity

“Within the cement industry, we are as known as Coca-Cola is in the soda industry.” This is how Søren Grubbe, VP of Supply Chain, introduces FLSmidth. Currently celebrating its 135th anniversary, it’s easy to see how the company has built such a reputation over more than a century. FLSmidth is a world-leading technology company which, through countless innovations in engineering, has pioneered the cement and mineral industries.

FLSmidth has a strategy, where it delivers projects, products, and services. “This is a very unique combination,” Grubbe comments. “Where many of our competitors are very much focused only on projects, or only products, or only services, we have the full end-to-end flowsheet of products. Also, we focus on the full lifecycle of a facility, both in the construction and operations phase. That's one of our key success factors.”

Sustainable productivity enhancement

Of course, to have enjoyed such longevity – surviving both world wars, which saw Denmark cut off and occupied – there are many factors behind FLSmidth’s success. “We actually have the expertise of all the different technologies that goes from when you get the limestone in a cement plant, to actually have the final cement in a bag,” Grubbe advises. “The same goes on the mining side.”

Such expertise helps FLSmidth drive efficiencies for its clients. The company wants to be the productivity provider number one, not only for its customers, but also internally. “We drive success through sustainable productivity enhancement,” states Grubbe. “We drive success for our customers by helping them improve their productivity, but we also drive success internally by improving our own internal productivity in our processes, ways of working, new tools and better visibility.”

Improving the flow

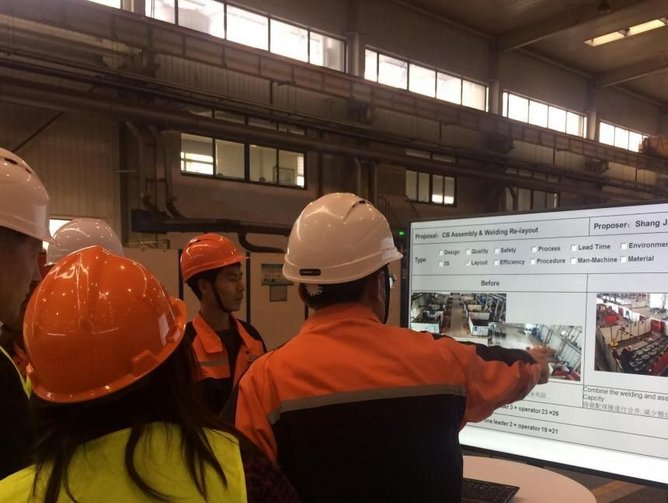

In response to this, the company has launched several programmes to help drive productivity. “The latest initiative I've started is what I call FLSmidth Production System. This is a programme focusing on our own internal factories that are producing parts, either for cement plants or mine sites. That programme is a tailor-made program for FLSmidth, where I have taken the best from the Lean world, the Six Sigma world, and then I added that into a theory of constraints philosophy,” Grubbe advises.

“What is important in our industry is that we can deliver fast and with high reliability. The flow is important, because the faster we can deliver, the faster our customers can make money, and the faster we can deliver them spare parts. Of course, the downtime is also reduced. Speed is very critical in our business.” FLSmidth is focusing on reducing lead time and enabling us to always deliver on time. “When we know the bottleneck, we can improve the bottleneck,” Grubbe continues. “We can improve the flow and an added value is that we also improve our productivity.”

Technavio market research analysts estimate the global cement industry to grow at a steady compound annual growth rate (CAGR) of more than 9% by 2020. With this in mind, productivity is clearly a strong focus for the future. FLSmidth has just launched this programme at its largest site in China, where 400 employees are based.

“We are very proud of that. We have got quite good results from this pilot programme. A lot of other plants are waiting in the queue to get on board into this programme,” observes Grubbe. FLSmidth used an external partner, Progressive Labs, to help develop this programme. “First of all, they have really brought a unique skillset of competencies that we didn't have ourselves, but they have also added some technology that has helped us synchronise engineering with procurement and production to one transparent and controllable flow,” enthuses Grubbe.

Focused on customers

With offices in more than 50 countries, FLSmidth is keen to ensure that it brings sustainable productivity enhancement to any new location it enters. “We have always been very focused on our customers, and having the intimacy to our customers, being at site, being very local. When we win a cement contract, we go in and hire locals. We bring experts to train them, and using local staff creates jobs in the local environment. That is really a boost to the country or region because it creates a lot of spinoff effects,” Grubbe explains.

“The governments support this business model, because it creates jobs and it improves the local economies. From a sustainability point of view, this business model ensures that we take responsibility for developing countries. Another aspect that we are continuously striving to improve is, of course, to minimise our environmental impact by developing products and solutions that use less energy. We limit the exhaust coming out of the cement plant by using our best-in-class filters. We have a unique water filter technology. We are industry leading in minimising water consumption and we are sending cleaner water out into the environment than our competitors.”

Unique products

Although FLSmidth is currently celebrating a milestone year, the company certainly shows no signs of slowing down. “We are seeing a huge growth in our service business, but also, FLSmidth has a lot of unique product companies, where we are selling products, not only to cement and mining sites, but also to other industries. We actually see a huge growth potential in these product companies, because these products are very unique and actually market leaders within their product niche. We are very much focusing on gearing up our entire organisation to be more focused on product deliveries, fast service, and really unique products,” Grubbe details. “That's where we are building our growth.”