With brands such as Foschini, Markham, Sportscene and @home under its belt, TFG is a name which is synonymous with retail. The company first set up shop in Johannesburg, South Africa, in 1925 and today, the retail giant has over 3,300 outlets in 34 countries across the globe.

Overseeing the logistics function within the TFG supply chain is Jan Tukker, Head of Logistics. Having worked at the company since 1998 in roles such as Systems Manager, Senior Financial Manager and beyond, Tukker is well-placed at the helm of the group’s logistics team.

TFG is widely regarded as one of the most successful and profitable retailers in South Africa. However, despite its success, the group is keen to evolve further by continually improving efficiency in its supply chain. “I’ve been with TFG for some time now and over that time we have significantly developed the logistical network and our supply chain processes,” Tukker says.

“Driving efficiency in our supply chain is very important to us. We still have plenty of opportunity to improve, whether that’s by enhancing our stock turn, our stock holding, or our replenishment speed.

“A huge amount of competition has come into South Africa and, like any retailer, we need to be more efficient and conscious of the small things to ensure that we continue to succeed. Therefore, continually enhancing processes that improve productivity and efficiency is crucial to us.”

Speed of service

As a forward-thinking company, TFG stocks trend-setting, fashionable items as well as products which will sell all year round and are easy to replenish. To ensure that these items remain on trend, agility or ‘speed of service’ is a vital area of focus.

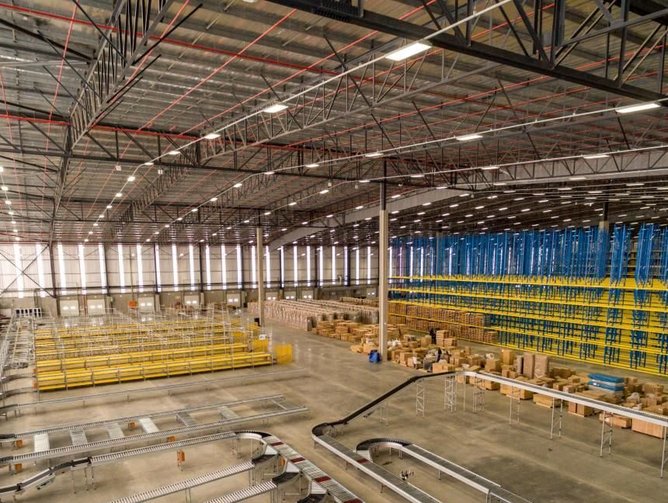

“For some of our retail brands, unit sales are growing quite rapidly partly due to negative inflation,” says Tukker. “As a result, our supply chain is under increasing pressure to quickly deliver these products. To manage this effectively we are developing and expanding our distribution centre capability.”

“We want to make sure our supply chain is agile by creating what we call multi-business distribution centres. These will allow suppliers to deliver to multiple distribution centres across the country rather than just the one which is available in the current systems and processes. This is a big project from a distribution centre footprint and IT point of view. We will be leveraging our investment with our WMS supplier, Manhattan Associates to make this happen.”

Visibility

Managing stock levels is critical for any retailer and with over 21 brands, visibility within the supply chain is more important to TFG than ever, says Tukker. “Visibility has been a big focus for TFG because it enables us to reduce stock, it allows us to know where our products are, and it allows us to improve our decision-making. It is an area where we are showcasing innovation in everything that we do.

“So, for instance, we are currently using software called Llamasoft Supply Chain Guru to model and evaluate our supply chain network from supplier all the way through to our customers. This enables us to optimise our supply chain by selecting the right locations for our distribution centres.”

Global footprint

Spanning several continents, TFG has a wide-reaching global footprint. In recent years, the company has procured numerous big-name retailers such as Phase Eight, Whistles and Damsel in a Dress in the UK and The Retail Apparel Group in Australia. “We are currently in a space in our organisation where we have procured other retailers not only in South Africa, but also Internationally,” says Tukker. “We continue to open stores in South Africa and in selected African countries, but are growing our international footprint at the same time.”

Whilst the company is targeting new territories, it has strategically targeted the value, mid and high customer segments within the market. “This is a strategic move which shields TFG from economic risks,” explains Tukker.

“If the economy declines and consumer spending is under pressure, people will want to buy value products and so we have strong value brands in Exact and The Fix. In the upper market we have brands such as Fabiani, @home and G-Star Raw. TFG has brands spanning all three of these markets positioning ourselves to capture all three of those market segments. This makes us a less risky as an investment opportunity because we cover all areas of the market.”

Driving efficiency

This large footprint hasn’t come without its challenges, particularly in South Africa. TFG has embarked on several projects using the Lean Methodology, whereby it aims to cut out waste from its supply chain. “Over time inefficiencies creep into processes which need to be reevaluated to remove unnecessary time and cost. We have multiple projects across our supply chain addressing these areas of waste, continually improving the way we work.”

“There are quite a few suppliers that have helped us to develop our Logistical Network to the level that it is at now,” comments Tukker. “Notably, a long-standing logistics partner of ours is the RTT Group. They are responsible for the transport from TFG’s distribution centres to our stores and in that process, they haven’t been just a trucking company, they have been valuable partner. They are now implementing a much more sophisticated, digital, delivery mechanism to stores allowing our stock position to be more visible. We’re also working with Adjuno, whose head office is in the UK, on developing improved supply chain collaboration between TFG and our stakeholders. This will result in better visibility of orders from suppliers into our DC’s and is all part of digitizing our supply chain.”

The road ahead

As a retail giant, TFG has captured the hearts of the South African and global market. But, with such visible successes, what is the company’s next move? “We’re going to continue to grow and become more efficient,” Tukker says. “Our online presence is growing quickly and more than 5% of revenue is generated through this channel. Customer centricity is a key focus for TFG and our Supply Chains need to ensure that ever increasing customer demands are met.”

“We will continue to drive efficiency, agility and visibility in our supply chains which will allow us to react quicker to sell better. We'll be analysing the data in our supply chain at a completely different level and are going to become more analytical. We’re driving to always understand global trends and improve our supply chain because, in retail, it is an ever-evolving world.”